When it comes to designing the perfect package, custom colors, stamping and embossing aren’t just for decoration. In fact, customized caps and closures help boost shelf impact, drive sales and build brand loyalty. Consider some revealing statistics about the impact of attractive packaging:

About 70% of purchase decisions are made at the shelf. The product has about three seconds to engage the consumer

Source: Store Brands

Roughly 64% of consumers will sometimes buy a product off the shelf without researching it first.

Source: Store Brands

-

Packaging drives 36% of purchase decisions—more than digital ads, TV ads or peer feedback.

Source: Affinnova/MeadWestvaco -

About 41% of consumers make a repeat purchase because of a product’s packaging.

Source: Affinnova/MeadWestvaco

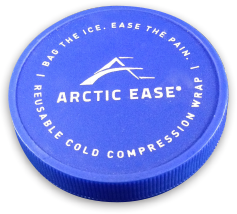

Check out this list of decorative options that will make your next package design stand out from the crowd:

Embossing and Debossing

Specific tool steel is procured to form the logo or lettering in plastic.

- Can be produced on most closure styles with the appropriate tooling changes

Tipping

Transfers a colored foil to an embossed part by a flat, hot rubber die (consumable). Requires a raised logo created by a mold insert to make an embossment that is stamped with the foil.

- High-quality look

- Lighter tipping colors remain opaque even over darker base colors

Hot Stamping

A colored foil is transferred to a part by an embossed, hot rubber die. Unlike tipping, the embossment is on the rubber die instead of in the cap mold. A logo design is cut into a consumable rubber die, which can stamp any color foil to the cap.

Offset Printing

Utilizes two rollers: one embossed with a logo and one covered with ink. Ink is transferred from a flat roller to an embossed logo on a second roller, which transfers the ink/artwork to a jar or closure. Multiple colored images can be printed.

- Since this is a continuous process, it can be achieved at relatively

high production rates, offering lowest conversion cost - Because the cost of ink is relatively low, this option offers the

lowest raw material cost - Multiple colors can be overlaid in stages by passing the part

under multiple rollers

Kiss Printing

Involves transferring a colored ink to an embossed part by printing rollers. Requires a raised logo created by a mold insert to make an embossment, which is ‘rolled over’ through an offset printing machine.

- Less costly version of tipping

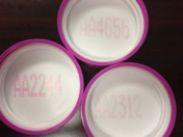

Ink Jet/Digital Printing

Utilizes ink jet spray heads to print ink on closure. Often used for promotional or small-run quantities.

- Enables highly flexible print design options that are

relatively easy to configure - Ink jet printing can provide an array of artwork—

from simple alphanumeric codes to complex images in millions

of color options—with a single pass

There’s more to learn about the Four Key Questions for Designing Great Packages.

The password to watch the video is weatherchem